Hollowcore Planks: Efficient and Durable Solutions for Building Construction

For over 90 years, Mack Industries has been a leader in the field of precast concrete, known for innovative solutions like the prestressed hollowcore planks. Since 2004, hollowcore slabs have been a major part of our offerings, providing essential advantages in commercial, residential, and industrial construction.

Why Choose Hollowcore Planks?

Hollowcore planks, often utilized as flooring, roofing, or wall panels, are ideal for projects requiring long spans without support from beneath. Concrete hollow core planks can span over 40 feet, making them an efficient alternative to traditional structures. Not only do hollowcore planks optimize building height, but they also speed up construction schedules as they are easy to install using cranes at the site.

Manufacturing Process

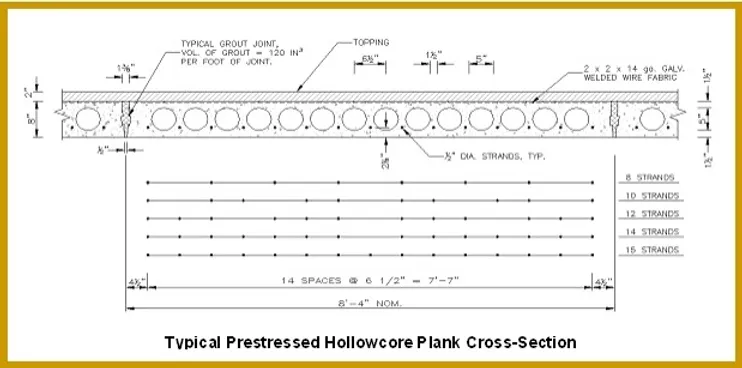

The process of creating hollowcore planks involves pouring low-slump concrete on a 500-foot casting bed where it is shaped using a slip-forming machine. This method incorporates high-tensile strength steel strands, tensioned to enhance load capacity and strength. Features like keyways and block-outs are added before the concrete slabs undergo curing to achieve maximum durability.

Once cured, these hollow core precast concrete floor panels are cut to required dimensions, ready for transport and installation. At the construction site, they are easily lifted and secured into place, providing a swift and reliable solution for building floors and walls.

Mack Industries: Leaders in Sustainable Hollowcore Plank Production

As a certified member of the Precast Prestressed Concrete Institute (PCI), Mack Industries adheres to the highest standards of production. Our commitment to sustainability is evident in our use of recycled materials, which can contribute towards LEED certification points under the U.S. Green Building Council’s Rating System.

STRONGER

Mack’s hollowcore slabs, available in thicknesses of 8″ and 10″, support extensive loads across spans of over 28 and 33 feet respectively. Enhanced further with a structural concrete topping, these panels achieve compression strength up to 7500 psi after 28 days.

FASTER

Our 8’4″ wide hollowcore planks are designed for rapid installation, significantly outpacing the standard offerings by competitors. With capacity to install over 8000 square feet daily, our skilled erection crews facilitate smoother project timelines, regardless of weather conditions.

BETTER

Engineered with features like welded wire fabric, Mack’s hollowcore planks exhibit minimal camber, ensuring superior structural integrity and surface smoothness. Additionally, the streamlined design reduces the need for extensive caulking, further speeding up the construction process.

All standard hollowcore products from Mack come with a 2-hour fire rating from Underwriter’s Laboratories, ensuring safety and compliance with building regulations.